Are portable air purifiers part of your building’s reopening plan? If so, you may want to consider adding Bert’s Plug Load Control solution to your air scrubbers. Bert saves money by automatically turning units off nights and weekends and restarting them in the morning before rooms are occupied. This reduces each purifier’s annual electrical expense by roughly 60%.

How Do Air Purifiers Help Buildings Reopen?

Portable HEPA filtration systems are also called air scrubbers. Units draw in air from the surrounding environment, use filters to remove contaminant particles, and recirculate filtered air. They can be an integral part of a multi-layered strategy to keep school buildings safe.

The Harvard T.H. Chan School of Public Health Healthy Buildings Team recommends that indoor rooms meet at least one of two air ventilation targets through a combination of fresh outdoor air, recirculated air filtered at MERV 13 level or higher (for rooms with mechanical ventilation), and the use of portable air cleaners with HEPA filters:

- At least 5.0 air changes per hour (ACH) of clean air—with the Healthy Buildings Team defining 4-5 ACH as “good,” 5-6 ACH as “excellent”, and 6+ ACH as “ideal”

- At least 15 liters per second per occupant of clean air, lowering the population density of rooms that cannot fully meet the ACH-based target as a complimentary ventilation strategy

To help building operators determine whether air scrubbers are needed, the Healthy Buildings team created a simple calculator. Enter variables such as room square footage, ceiling height, outdoor ventilation level, and air purifier capacity. The tool indicates whether the room meets the ACH target with the proposed air scrubber.

How Much Do Air Scrubbers Cost to Operate?

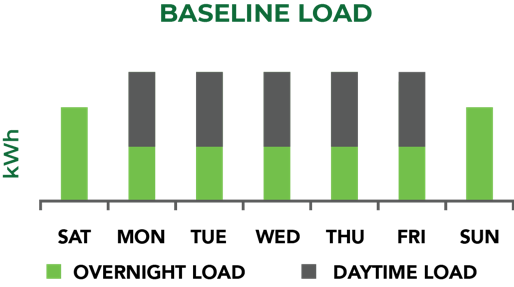

Portable air purifiers are not connected to HVAC systems. They run 24/7 unless someone physically turns the unit off. Annual costs to operate a scrubber vary based on kWh rate, operating wattage, and operating hours. Annual Energy cost ranges from $92 for lower-end 400 CFM units ( $.11 kWh) to $ 2,170 for high-end commercial 1,500 CFM units ($.18 kWh). To determine potential energy savings for scrubbers in your building, use the Air Purifier Energy Savings Calculator shown below.

Enter the wattage, kWh rate and select the number of ON hours. Annual electrical expenses with and without Bert are calculated, along with the annual $ savings.

How Does Bert Control My Air Scrubbers?

Installation is easy. Each air scrubber is plugged into a Bert Smart Plug, which is plugged into an existing wall outlet. The Bert uses the existing wireless network to check for schedule updates and to send real-time measurement data from the air scrubber. Berts are scheduled and grouped by HVAC zone, building, building group, or other user-specific group. Administrators can view the relay state and communication status for each unit.

Every Bert stores its schedule locally. As a result, Berts will continue to turn air scrubbers on and off even if the wireless network is down. Berts also have an override button that allows individual users to turn air scrubbers on manually if needed.

Frequently installed as a standalone solution, Bert delivers even greater value when integrated into BACnet/IP building automation systems or web-based applications because air scrubbers can be managed in context with the other building loads. For example, occupancy sensors can trigger the BAS to turn air purifiers on.

Bert does more than controlling air purifiers. Bert’s Plug Load Control solution monitors and controls other plug and hardwired building loads, including electric hot water heaters, air handling units, exhaust fans, AC units, vending machines and other electronic devices in over 10,000 buildings. Bert controls loads ranging from individual 120V/15A loads to 277V/20A, at either the device or circuit level. In most cases, the annual payback to install Bert is less than one year.

Contact Bert to learn more about controlling air purifiers.